From cosmetics to pharmaceuticals, from homecare products to food & beverage, shrink sleeve labels can be the winning

From cosmetics to pharmaceuticals, from homecare products to food & beverage, shrink sleeve labels can be the winning choice in terms of aesthetic results, resistance, sequencing speed, printability, reduced costs, communication potential and, last but not least, recyclability. But at a time when plastic is at the eye of the storm, the challenge to innovation is more pressing than ever.

By Lorenzo Capitani | On PRINT 80

Serendipity: the good luck of making happy discoveries… by chance. This is how ice lollies, Velcro and shrink sleeve labels came into being: in 1965 the Japanese company Fuji Carpentry had to protect its barrels of sakè from tampering and had the great idea of using a plastic film to protect the taps. The heat from the fermentation did the rest of the job and now that small company, founded in 1897 for the production of wooden barrels, has become Fuji Seal International, with 5,000 employees in three different continents.

A Billionaire Business

The shrink sleeve labels market – Shrink or Stretch Sleeve – has developed on a wide scale since the 80s and it is now a flourishing one predicted to grow by 5.75% between 2018 and 2025; it also has a turnover that went from $10 billion in 2017 to a predicted $15.64 billion in 2025. In every section of today’s market, 20% of labels are shrink sleeve labels: from food to beverage, from pharmaceuticals to nutrition, from Health & Beauty to homecare products. The qualities of this type of label make it the best choice both in terms of product communication and its use. On the other hand, an influential aspect on its use is how plastic is being used, an issue that has been growing recently because of environmental sensitivity.

The Silent Salesman

The main purpose of a label is communicating the content of the packaging and the related mandatory information, but with time labels have become one with packaging until they became a marketing strategy. Is it really enough for a product to be useful, functional or necessary in order for a consumer to consider it better and buy it? Obviously not. Giving a product the caption ‘Made in Italy’ makes it almost automatically more desirable than the same product from China. As a good ‘silent salesman’ would do, packaging becomes more than mere wrapping: it shows the story and values of the brand and leads the consumer to make more purchases. Quoting Seth Godin, one of the greatest marketing gurus: “the purpose is telling stories, not dreaming up ads”. The label becoming the packaging – which is the case for shrink sleeve labels – is the perfect marriage: the functional and aesthetic values merge. The product is protected and communicated at the same time.

Anatomy of a Sleeve

What are shrink sleeve labels made of? There are two types: the Stretch Sleeve, also called wrap-around, which is cylindrical and only covers a part of the container, and the Shrink Sleeve. In general, sleeve labels are simply a tubular plastic film of shrink sleeve material and they adapt in every possible way to the primary packaging (sometimes even the secondary one, for example with crates of water or drinks). The thickness can vary from 40 to 50 micron, up to a maximum of 70, but sectors such as food and beverages, home-care and toiletries can go down to 30/35 micron for cheaper wrap-around labels.

Stretch Sleeves

These are the most economical and are made up of a heat-treated seam in plastic that wraps around part of the content. The application is done cold except at the point of the heat treatment. The system uses tubular labels in stretch film, pre-cut in order to separate the labels that are simply pulled by the lower flap and fitted on the container, which should preferably be cylindrical. Thanks to the elasticity of the film the labels do not need adhesives or thermal processes to attach perfectly to the container, which can be both full and empty, wet or dry: the labelling can therefore be done before or after filling. In general they are used when the labelling may be of reduced sizes (detergents), when heat cannot be used or the colour of the product – in the case of transparent containers – is important (bottled water) or again when the cost of the packaging has to be reduced as much as possible. Stretch labels also enable bulk packaging, in other words the packaging of several pieces to create groupages of products made even of different materials. The films may be of different compositions but among those most used there is PVC – the most economical with good abrasion resistance – LDPE (low density polyethylene), PP and PET, which offers the highest rub resistance, greatest brilliance and clarity, and thermal and chemical resistance. The same materials are used for the containers, enabling disposal and recycling of the packaging without having to separate the materials. An interesting marketing idea connected to the disposal of these packages is (Re)Collection, a 12-piece capsule collection produced by Diesel with recycled materials. The collection incorporates materials such as recycled PET derived from plastic bottles and recycled cotton; it can be purchased simply by scanning any recycling logo all over the world which will access an exclusive site on diesel.com for e-commerce.

Shrink Sleeves

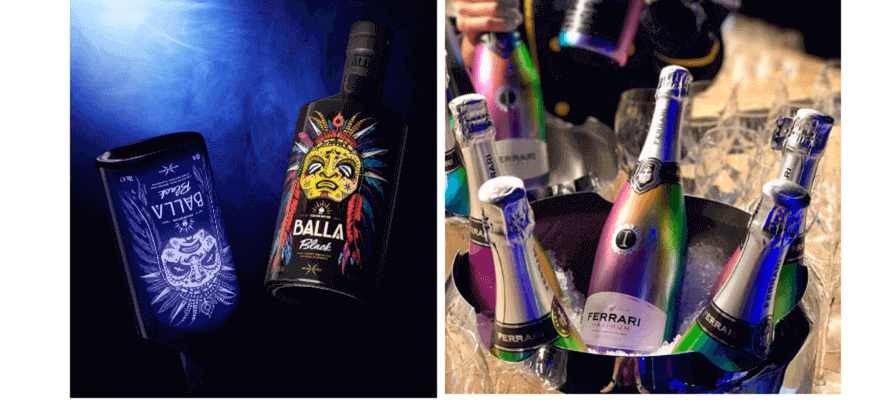

But it’s Shrink Sleeve labels that are offering the greatest possibilities today. They are actually tubular, shrink labels in plastic that perfectly and entirely fit every shape of container thanks to their shrinkage capacity of over 75%. The advantages are undeniable, as Lucie Ray-Lalanna, Communications Director of Sleever International, points out: “The container’s decoration can be done entirely at 360°, even on extremely complex shapes. Then there’s the printing – which for us gets to 10 colours – and the great number of effects that can be had to decorate or to simulate materials or finishings, for example. We shouldn’t forget either the possibility of covering a wide range of materials, such as plastic and glass, whether full or empty according to the demands of the filling lines (they are even resistant to pasteurization). And finally, their flexibility and time-to-market are vital for the consumer goods market.” Bulk packaging is also possible with shrink labels: in addition, if they are extended as far as the openings, they can also act as a seal of warranty, which is particularly interesting for products that have to guarantee their absolute integrity.

“This type of label costs 25% more than a traditional adhesive label,” said Mark Hill – Vice President and Head of Research and Development at INX International Ink Co, the third biggest American producer of inks and coatings – in a recent interview, “but it can offer a return on investment of over 150%.” The film’s thickness – in PVC, PET-G, PP, PLA, OPS and PE – protects the container from abrasion or perforations and the container from light thanks to treatments and inks that make the sleeves a genuine barrier. Disposal and recycling are made extremely simple since they can use single-material packaging (e.g. PET bottles and PET sleeves) that does not use pollutant chemical adhesives. “Its cost per impression, resistance, recyclability, and the fact it can itself be the product’s warranty,” Hill went on, “are all factors that determine this technology’s success.” It is no coincidence then that the brands paying most attention to performance and design use shrink labels that at times make it almost impossible to notice the label itself. This is the case with Mumm, Smirnoff and Sky Wodka who have had their bottles “dressed” by CCL Label or with Wolfberger (a prestigious wine producer in Alsace), Moët & Chandon and Veuve Ambal, who turned to Sleever International.

Production

How is a sleeve label produced? There really are endless possibilities with excellent results both in the materials’ performance and production quality, with even the possibility of personalising the label as a single piece. Starting off from the design, the technological possibilities are really advanced. The starting point is the container’s dimensions and then the distensions imposed by the shapes have to be taken into account. For example, in the case of a bottle the high part and the lower part – called High Shrink Areas – are reserved for product information while the graphics go in the central part. Software such as Studio from Esko provides solutions like Studio Toolkit for Shrink Sleeves for the creation of sleeve labels that take shapes and materials into account, calculate the distortions and shrinkages and automatically apply all the compensations. The result is a 3D simulation of the sleeve which can be viewed directly in Adobe Illustrator where the materials can be changed dynamically and a 3D PDF can come out without using a trial and error process.

For both types of film the printing can be carried out in flexo, rotogravure or offset with a range of colours from four-colour + pantone up to 11 colours. There are also solutions that combine various technologies on the same machine, like at Maer Italia where there is a nine-colour machine with combined offset, silk-screen, flexo, hot and cold printing, and lamination. ACM Plastic, one of the leading companies in Europe to have invested in heptachrome printing, has a narrow web flexo plant with LED drying: 7 fixed colours in the machine – orange, green and violet as well as the 4 basic colours that ensure more natural and intense colours, increasing colour saturation by 95% and reducing the use of Pantone palettes.

The possible enhancements are also of note, with effects from pearlescent to metallic to mirrored; it is possible to print white, gold and silver cold foil but also to use gloss or matte coatings and special inks. The American MCC Label, which also has four locations in Italy, has created luminescent shrink labels for Colgate with an ink that maintains its features even after thermal shrinkage. It has also covered Hubert’s Lemonade bottles with a label with a particular raised texture that imitates the tactile sensation of a real lemon, encouraging consumers to touch the product. Then there are functional solutions such as the printing of labels that gradually change colour as the bottle empties or if it has been subject to processes like cold pasteurisation. But actually it is with digital printing that the best results are achieved, especially in the context of personalisation. Digital is now the state of the art also for sleeve labels and there are countless projects that have been created. The range includes: the Coca-Cola bottles produced by the Nuceria Group; Danone’s Actimel (coated by I.B.E with the creativity of Creostudios) that are all different so as to create your own football team; Wacko’s crisps (in co-branding with the Milano Games Week 2019) with the container personalised with the name of the favourite player and YouTuber. All these projects were developed within Brand Revolution LAB. But there’s also Nutella with its “Nutella Unica” (Unique Nutella) and “Nutella gemella” (Twin Nutella) campaign, Heineken and Pril – all solutions created digitally on Indigo machines with the aid of SmartStream Mosaic software for variable data management.

Paying attention to the environment

The success of sleeve labels lies entirely in the plastics used: no paper and adhesive; high processing speed; stability; resistance; protection; ductility and ease in decorating and processing; high aesthetic level, and absolutely competitive costs. And yet it is these plastics that represent the biggest problem for the environment. PE, PP, PVC, PET and OPS – the polystyrene used so much today because of its high degree of transparency – are all 100% recyclable. However, the National Consortium for the Collection and Recycling of Plastic Packages (Corepla) estimates that in Italy only 43.5% is recycled, 40% ends up in waste-to-energy plants and 16.5% in landfill. And possible future taxes will do little to help until a responsible use of plastic becomes widespread. In addition, not mixing the types is vital in the recycling phase so as to obtain quality plastic. In the meantime, before the backlash the environmental movements and legislation against single-use plastics will have on the market, the producers are putting forward plastic films that are not only recyclable but also eco-friendly.

On the one hand, there is an attempt to reduce the environmental impact during production. This is what Crocco S.p.A, a leading company in the production of flexible plastic packaging, is doing, as is Granarolo, in order to reduce and neutralise their CO2 emissions. Likewise, the UK company Leading Edge Labels and Packaging is doing so to reduce the use of energy not produced from renewable sources or of UV lamps when they are not necessary. On the other hand, there is an attempt to use entirely recyclable materials, including the inks, which facilitate recovery. At Fachpack 2019 in Nuremberg, Folienprint RAKO presented a film for sleeve labels that can easily be separated from the PET flakes during recycling and Sleever International has done the same with its low density LDPET: the LDPET flakes float while those from the PET bottles sink and can be easily recycled and recovered. Filmo Group has gone further and for its films uses PLA (polylactic acid), in other words a bio-plastic shrink label – 100% bio-degradable and bio-compostable, derived from plants such as corn, cassava and sweet potatoes. Once it has decomposed, it does not release harmful substances into the atmosphere but instead permits the regeneration of the raw material. It is highly transparent with a very shiny effect, excellent printability and good shrinkage levels to adapt to almost all container shapes as well as having good abrasion resistance. Meanwhile, there are those attempting a great leap forwards: on 10 October, Carlsberg presented two recyclable prototypes of a bottle in wood fibre from renewable sources. One of the bottles is completely coated with a thin film of recycled plastic while the other is coated with an organic material. Might this be the start of a revolution?

Three questions to Lucie Ray-Lalanne, Head of Communication, and Sofiane Mameri, Sustainable Development Manager at Sleever International, a multinational specializing in the production of shrink sleeves.

–

What kind of material do you use? And what about the printing technologies and enhancements used for producing your labels?

Sleever is the only shrink sleeve producer who has completed a vertical integration of the process, from the film formulation to the services, including the printing process, shrinking operation, machine conception and manufacturing. We currently produce more than 60 different film formulations, a major part of them being composed around PET. According to each project’s specification, we can offer the most appropriate combination of printing techniques and sequencing. We actually do offer many different printing techniques and operations, like rotogravure, flexography, offset, digital printing… and combined printing machines. We also provide cold stamping operations, and offer metalized, touch, special UV or special luminescent effects.

How is the shrink sleeve label market reacting to the request to reduce plastic, especially with ecological movements such as Greta Thunberg’s?

Sleever has been working for many years on sustainable packaging solutions, and cooperates with brands on eco-conception, to create recyclable or reusable packagings. The idea is to provide the brands with premium differentiation solutions that won’t disrupt the recycling process and facilitate the packaging’s recyclability. For instance, we won several awards, including one at Pack Expo Las Vegas a month ago, with the LDPET® product, a low density film printed with non-bleeding inks, that allows the full recyclability of clear PET Bottles. We also developed products and solutions to reduce carbon footprint by reducing our material quantity (sleeve thickness) and energy consumption (sleeves and machines). Shrink sleeves are a non-definitive decoration technique, without adhesive. Our products with premium differentiation also allow brands to reduce the material quantity of their primary packaging, or use packaging with a strong percentage of recycled material.

What are your strategies to make your 7packaging as easy to dispose of as possible and the most eco-friendly?

As a non-adhesive, non-permanent decoration, shrink sleeve is already a facilitator of recyclability for glass and plastics packagings. Our LDPET product was designed to fit into the clear PET recycling process and be easily separated from the bottles to allow the generation of a food-grade PET. The sleeve itself will be completely recovered as fibres for synthetic materials, for instance. We have been working for more than 15 years on the subject and implemented LDPET on several worldwide scale mineral waters products, for major players. We are now working on expanding our expertise to other market segments.