Let’s discover the enormous potential children’s products have towards a more sustainable lifestyle

Reduce, reuse, recycle. If there is one area where the three great “R’s” that drive change towards a more sustainable lifestyle can express enormous potential, it is that of children’s products. This is possible through packaging that can be reused and become an open-structure game: a challenge of simplicity and creative thinking that can also be used in other areas. We talked about it with three experts who have tackled the different facets of the theme in their work: Oscar Diaz, the inventor of the Tube Toys; Alberto Quercetti, Director of Research & Development at Quercetti, an Italian company specialising in educational games; Kitty De Groot, founder of Studio VIX and former director of Research & Development at Joolz, a Dutch brand of pushchairs that came into being under the banner of the circular economy.

By Roberta Ragona | On PRINTlovers #84

In the spring of 2020, among the many upheavals caused by the Covid-19 emergency, there was a subtle but significant change in habits of a group of consumers with particular tastes: children. According to data provided by Criteo, sales of construction toys began to rise dramatically around the world in mid-March and have remained well above historical levels ever since. In Italy alone, over 30 days – from 27 March to 26 April – sales grew by over 60% compared to the average for the period. The increased number of hours spent at home by children has brought back to the forefront entertainment modes based on the manipulation of materials, observation and exploration of the different possibilities of interaction, and therefore capable of stimulating creative thinking. In this open-structure play mode, packaging plays a fundamental role as well. It must go beyond the simple function of protecting the product; it has to become raw material and have a transformable nature that can be incorporated into the interaction.

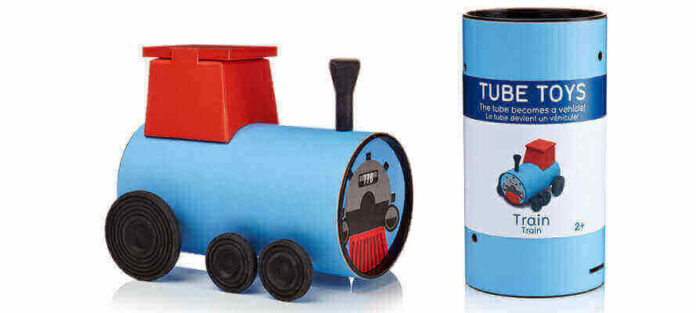

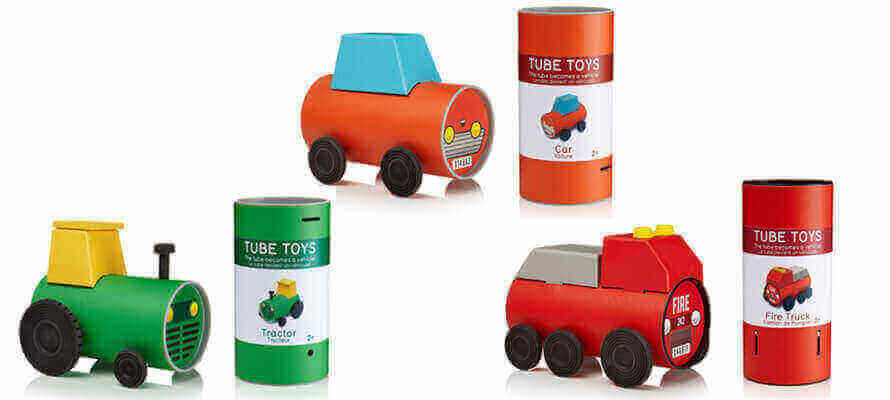

“Packaging nowadays is an extension of the product, the first impact that the buyer has with the brand at the time of purchase,” says Oscar Diaz, a Spanish-born designer based in London who is an expert in the design of open-structure games. Diaz has developed the Tube Toys, an innovative concept in which packaging is nothing more than the mainframe of the game: already a classic in the most inventive toy shops and gift shops in museums around the world. “This experience must be able to communicate the values of the company that produces it, and the object itself,” continues Diaz. “The questions that follow, such as, “Is it easy to open? Should I read the instructions? Does it look like it was made specifically for me?” or the sensations, “Does the packaging have a certain smell?”, drive the design: everything must align with the brand in terms of style, tone of voice and quality. Consumers are bombarded with choice options, and this also applies to children. The quality of the experience as a whole can make the difference between a product that stands out from the rest, or not”.

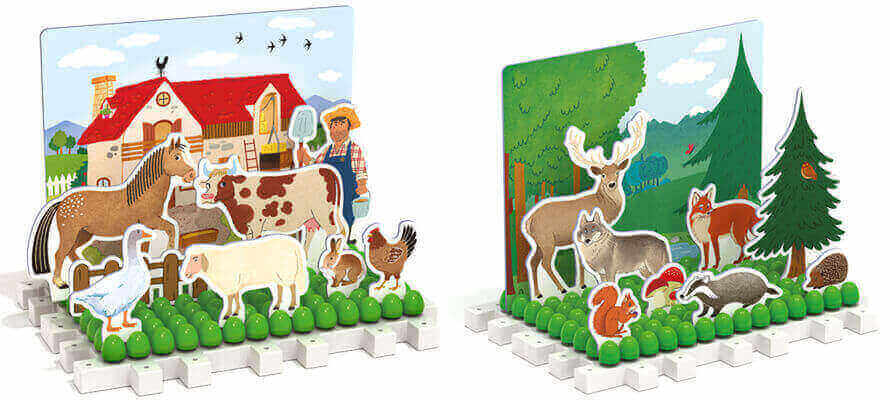

The principle of packaging as a fundamental communication tool is the basis for the choices of Quercetti, a Turin-based company that has been producing educational games for seventy years. Alberto Quercetti, son of the founder Alessandro and director of the Research and Development department, tells us: “We try to invest everything in the product and the communicative potential of the pack, we take particular care of it both from a paper making point of view and a design point of view, from the composition of the cardboard to the safety aspects and ease of use, which are obviously central themes in our work.” And regarding what distinguishes the company’s choices from those of its competitors, he continues: “Our approach goes against the tide when compared to the trends of big generalist players. For example, take the classic box with aeroplane flaps, a very popular type in our sector. We rarely use it because it requires the glueing of one side of the box, and we prefer self-assembling boxes without glueing. This guarantees a lower environmental impact and a significant difference in the long-term durability of the pack. We always try to give something extra to our customers.”

From 2009 to 2017 Kitty De Groot was head of the R&D department of Joolz, a Dutch brand of ergonomically designed pushchairs, where the circularity of the raw materials and their versatility is reflected in both the products and the packaging. She explains how the idea of giving something more to consumers was the spark at the basis of Joolz’s transformable packaging. De Groot and her team developed the concept of printing instructions on the packaging to transform it into dozens of fantastic shapes: birdhouses, hot-air balloons, elephants, aeroplanes and much more. Thus, transforming cardboard from waste material to the surprising raw material needed for new forms of interaction.

“I worked on the idea of making transformable packaging during my ten years of experience at Joolz before opening my own design studio, Studio VIX,” says De Groot. “We started with the idea that it was a shame that material as strong and full of potential as large cardboard boxes would be thrown away immediately after discarding pushchairs and other products. We started with three designs: a chair, a birdhouse and a chandelier. Then we gradually expanded the catalogue with new toys to build for each new model of pushchair and accessory. The idea was to build an entire playroom in cardboard, where children could play in peace: a positive and joyful environment built by adults and children together, sharing a stimulating activity”.

Not wasting a versatile material is also the principle that guided Oscar Diaz in the design of the Tube Toys: “The idea of a packaging that becomes part of the game itself was born seeing too many examples of over-packaging. Consumers demand more sustainable solutions, so I thought it would be interesting to reduce the packaging to the bare minimum. An important characteristic of toys is that children change very quickly, and so do their interests: it was important that the packaging was protection, part of the game and then recyclable material with as little impact as possible.

Therefore, maintaining the integrity of the product with a lighter design becomes the cornerstone of the project for Diaz: “The most challenging thing was to make sure that, while reducing the packaging, the toy was still protected and didn’t get to customers damaged. I made a risk assessment, considering all the stages through which the product goes through, from production to the shelves of the shop, and I realised that – since the games were shipped in packs of 24 pieces – the only time they could be damaged would be when they were displayed on the shelves. I added a plastic film around the packaging to protect it from moisture during transport, so I was able to reduce the packaging used by 80% compared to other toys in the same category. Among the different materials available to designers when working on transformable packaging, cardboard has one feature that makes it perfect for projects dedicated to children – safety. As Kitty De Groot points out: “The beauty of cardboard is that it is a material with no hard or sharp parts. There is no need to add anything else or use other materials. Having worked as a pushchair designer, I am deeply aware of the safety aspects to consider when making a toy from packaging materials”.

Of course, environmental sustainability is as much at the centre of the discussion in the children’s market as it is in the generalist panorama. Quercetti points out that product sustainability is a value of the entire supply chain, not just a marketing theme: “The entire life cycle of play and packaging must be taken into account. Our product is entirely made in Italy, from the games themselves to the packaging. We do everything within a close range from us. We have trusted partners such as Cartotecnica Lampo and Hard Color, specialists of die-cutting, flute size B cardboard and experts for special processes made with thick cardboard”.

And concerning the future of the sector, Quercetti stresses that there is much potential: “I think there is still a lot to be invented, starting from the fact that customer demand is increasingly moving in the direction of green materials, both for games and packaging, which translates into mono-material packaging and games to facilitate recycling. In recent weeks, we have launched a line called Playbio, with a flute size B cardboard packaging and matt varnish printing, rather than the glossy printing that is usually seen in toy packaging, and for the games, we have used plastics with 40% wood fibre. But putting sustainability at the forefront like this requires a mature and informed audience. Much will be played on the design,” concludes Quercetti, “and we are working on transformable packaging that contains elements that have a life together with the product, such as interiors that become frames for the pictures in the Pixel Art kits, and the most recent incarnation of one of our most famous products, the Chiodino, a classic toy that seems to have been inspired by four-colour printing.

And if the adult public carries with them a wealth of habits and customs that any packaging innovation must necessarily deal with, then in the case of children it is their entire life experience that is marked by continuous transformation: a fertile ground on which to plant the seeds of change.