Arconvert presents its new Brand Protection catalogue of self-adhesive materials containing security elements

New research published in June 2018 by the EUIPO (European Intellectual Property Organisation) shows that about sixty billion euros are lost every year in Europe due to counterfeiting.

According to the report, since legitimate manufacturers produce less than they would have done if there had been no counterfeiting, and thus employ fewer people, the direct losses in vulnerable sectors in Europe lead to 434.000 fewer jobs.

In Italy, the counterfeit products on the market result in annual losses equivalent to 7.9% of direct sales and the annual amount is about 8.6 billion euros, or 142 euros for each Italian citizen.

On a global level, the forecasts of the OECD (Organisation for Economic Co-operation and Development) indicate that trade in counterfeit goods will be worth more than 950 billion US dollars by 2022.

The sectors most affected by this phenomenon are fashion, electronics and food and beverages. However, counterfeiting and falsification do not only cause economic damage but also have a serious impact on personal safety, as is the case with counterfeit pharmaceuticals, food and beverages, medical equipment and toys.

Thanks to the Securtack brand, Arconvert is also known internationally as one of the leading manufacturers of self-adhesive materials containing security elements used by government agencies around the world and in the brand protection industry. Arconvert's R&D department is constantly committed to testing out the latest technologies in order to produce increasingly high-performing secure products, which represent the state of the art in anti-counterfeiting technological innovation, to ensure the authenticity of the product, luxury high-quality brands such as, Made in Italy and the indications of origin.

Arconvert's newest addition, the Securtack brand protection catalogue, is a meticulous selection of nineteen self-adhesive products including papers containing security elements, void, delaminants, ultra-destructible, holographic and, last but not least, RFID technologies.

Self-adhesive papers with invisible fluorescent synthetic fibres and coated papers free from optical bleach are the materials used to create, for example, warranty seals, stamps and VISA. Voids, on the other hand, are plastic films of different colours that, when the label is removed, the word “void” can be released - however this can be customised - or a chromatic variation may be applied. Similarly, there are also other self-adhesive materials that delaminate themselves, making any attempt to tamper evident because the surface of the label will appear compromised. Ultra-destructible films are another possible security element that can be used for over-labelling medicines or as a protection and anti-tampering device of products using a registered trademark. Self-adhesive materials with holographic elements are generally used for the realization of security, promotional and decorative labels. Each holographic label is, in itself, a security element. In fact, without the original holographic printing matrix (master), it is virtually impossible to reproduce an identical copy of an original hologram.

Finally, the catalogue includes two modern RFID nanotechnologies: UHF and NFC.

The counterfeiting market has gradually benefitted from the development of digital technology thanks to e-commerce, with a guarantee of anonymity and the increasing ease and speed that websites can be created or deleted. However, while the development of counterfeiting and falsification is facilitated by digital technology, these two markets are being hindered by the use of smart labels.

Thanks to new security technologies, smart labels play a dual role of communicating and guaranteeing originality, uniqueness and integrity and they could become the solution to protect brands and products in order to solve the problem of counterfeiting and falsification once and for all.

Securtech RFID technology has three huge advantages over traditional barcodes and magnetic stripes. RFID devices are "unique" because each chip has a unique and exclusive code that cannot be modified; "automatic" because reading it does not require any manual action and "incremental" because the information contained in the tag can be modified and updated as required.

The use of UHF tags - a technology that enables data to be sent and received at a distance of up to 500 linear metres - is growing rapidly, and the label manufacturers that have chosen to use them for their customers are already gaining a higher market share compared to their competitors. Just think that in a tenth of a second, for example, you can find out the number of items of a chipped article present in a warehouse. Meanwhile the food sector, where margins are normally low, is increasingly implementing the use of UHF technology to reduce food losses by up to 30% and companies in the health and pharmaceutical sectors feel much more secure thanks to the powerful anti-counterfeiting function of UHF self-adhesive labels used on the medicines marketed.

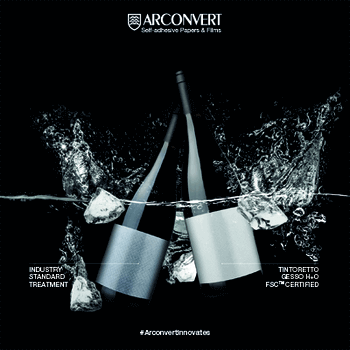

At the same time, from fashion to food and beverages, the producers of goods have realised that NFC (proximity communication) is not only an infallible anti-counterfeiting ally for high quality products. It is also a powerful and effective tool for communication and interaction with users and can even become a data collector. An example of the use of the NFC tag is in the wine industry. Some prestigious Italian brands have already implemented the use of NFC self-adhesive labels on bottles for the main purpose of preventing counterfeiting of their brand, since with the simple use of a latest generation smartphone or tablet, consumers can ensure they have purchased an original bottle and not a fake one. Secondly, the NFC label is also the real gateway to the brand because it informs consumers about the special features of the bottle they are intending to buy, providing information about the date of production, the characteristics of the wine and advice on the best way to consume it.

In Securtech RFID products, Arconvert inserts the chip and antenna directly into the self-adhesive sandwich. In this way, the nanochip inserted into the self-adhesive material is invisible and only a few people in the production chain are aware of it. Securtech RFID technology can be adapted to most of Arconvert’s face stocks, even to the most precious ones produced by the parent company Fedrigoni S.p.A. The synergy between both companies allows real coordinated packaging to be created, from the self-adhesive label to the box, from the shopper to the brochure, making it possible to achieve such high aesthetic standards that will inevitably attract the attention of consumers. A second, but no less significant advantage, is the possibility of inserting anti-counterfeiting devices into each individual component of the packaging and ensuring its presence is kept hidden from the production cycle to the delivery.

Arconvert, with its Brand Protection catalogue, is available to provide pre- and post-sales technical support, with a highly specialised support team that can analyse the application and suggest the most suitable material and techniques for the printing and converting technology to be used. In order to best meet the needs of all the main players in the supply chain, Arconvert offers a free consulting service not only for label designers and label manufacturers, but also for the producers themselves.

PHOTOGRAPHY CAPTION:

Credits: The Securtack Brand Protection catalogue was designed by SGA corporate & packaging design and produced by Intergrafica Verona S.r.l.

Contatti

-

Commerciale

Chiara Tomasi

344 25 49 087

chiara_tomasi[chiocciola]arconvert.com

-

Amministrazione

Chiara Tomasi

344 25 49 087

chiara_tomasi[chiocciola]arconvert.com