The devil wears a tracksuit

The growth of sportswear represents an opportunity for printers operating in specialised and large-format printing. Digital is the only technology able to guarantee versatility, extreme customisation and the possibility to produce in small quantities with technical and high-performance fabrics.

By Caterina Pucci | on PRINTlovers 99

There was a time, albeit a distant one, when sportswear did not exist. Playing tennis or riding a horse were activities in casual clothes, but nothing could be further from the breathable fabrics, seamless t-shirts and technical shoes we are used to. An early, embryonic concept of 'sportswear' emerged in the 1920s and 1930s: Jean René Lacoste launched the first polo shirts marked with the iconic crocodile, and Elsa Schiaparelli presented her first Pour le Sport collection. But in the 1970s and 1980s, sportswear achieved its consecration, thanks to Jane Fonda's unforgettable workouts and the spread of technical fabrics such as Lycra and spandex, designed to follow the body's movements. The 1990s saw the rise of athleisure, the trend of wearing clothes designed initially for sporting activities, even in glamorous or formal contexts, and of trainer culture, i.e. collecting sports shoes. Starting with Calvin Klein and Tommy Hilfiger, there has been a progressive contamination between fashion and sport - two traditionally distant universes - culminating at the beginning of the year 2000 with the advent of streetwear. These were the years of consecration of Virgil Abloh, founder of the Off-White brand and creative director of Louis Vuitton until his premature death in 2021, who was nicknamed by some the " King Midas of streetwear" because of his inimitable ability to elevate casual garments to cult status, exclusively in limited editions, often sold out within hours of their launch.

Today, the boundaries between fashion and sport are so blurred as to make them superimposable. This is well described in a book published a few months ago, 'The New Luxury: Defining the Aspirational in the Age of Hype', which says that luxury today is no longer based on an idea of ostentation of wealth but on a shared stylistic code, a question of belonging in which even a team strip can become iconic.

This phenomenon has been accelerated by the pandemic that, perhaps due to the long periods spent indoors, has directed purchasing preferences towards comfortable and sporty clothing, in step with the desire to lead a healthier and more active lifestyle. According to consultancy firm McKinsey & Company, the global sportswear market was worth $295 billion in 2021 and is forecast to reach $394 billion by 2025, with an annual growth rate of 8-10%. Brands have quickly adapted to this new demand, churning out new capsule collections such as Supreme for Louis Vuitton, Air Jordan for Dior, Prada for Adidas, or even the collaboration between Gucci and Major League Baseball in the United States. This hybridisation has meant that the characteristics that were once specific to sportswear (practicality, durability, resistance to abrasion or wear and tear) have become a standard also shared by the world of luxury, which creates its own collections trying to maintain a balance between elegance and comfort.

All these transformations are an excellent opportunity for textile printers, especially those working in large-format printing. Digital is the only technology capable of meeting the new demands of the market, which requires quality, versatility, extreme customisation and the possibility to print in reduced quantities.

In these pages, we will see how some professionals in the sector are facing the challenges imposed by this paradigm shift.

Extreme customisation and the success of made-to-order

One of Abloh's objectives was always to 'ennoble the anonymous', making everyday objects that often go unnoticed unique. It is not surprising that, within hours of his death, collectors had begun to wage war to get hold of at least one of the iconic trainers the designer made throughout his career, making some Off-White, Nike and Louis Vuitton models authentic cult objects. Like the ones made in 2018, at Anne Wintour's request, for the Parisian football team Melting Passes, composed of undocumented migrants. On that occasion, Abloh designed a kit in which the athletes could take to the pitch feeling like a real team. Each top was distinguished from the other by the presence of unique details, reflecting the need for customisation and contradicting the meaning of the ‘uniform’, enhancing the specific features of each one.

The ability to customise garments and accessories at will has become the real added value that distinguishes them from fast fashion. This applies not only to the big names in luxury but also sports brands such as Nike, Adidas, and Supreme, which for years have espoused the logic of 'made to order', allowing their customers to choose the model, colour, upper, and print for the heel and insole. All at competitive prices and simply and intuitively, following online instructions to configure your dream model step by step.

To each their own technology

Over recent decades, textile printing technologies have evolved rapidly, and alternatives to traditional screen printing have become more and more powerful. Dye-sublimation printing technology has become one of the most popular in sportswear printing because of its ability to guarantee high colour yield at low cost. Direct-to-garment or DTG printing perfectly matches the needs of the new generation of online printers because it allows short runs with a high degree of customisation. Very recently, the direct-to-film or DTF technique has taken off, which is particularly suitable for printing sportswear and workwear. The latter requires no pre-treatment and is, therefore, more versatile and economical than other standard film or flock foil decoration processes, not least because many printers with a pre-existing sportswear business already have a heat press and/or a polymerization (or curing) oven. Another advantage is that many transfer or direct-to-fabric printing technologies can be easily converted to DTF printers by simply changing the ink set.

This type of printing requires dedicated inks that are applied on a film with a thickness of approximately 0.75 mm. White is needed as a base to ensure that the colours stand out even on dark fabrics. Once printed, the films are coated with a hot adhesive powder while the ink is still wet. This operation is carried out manually in short runs, while automated solutions are preferred in industrial-scale production. Subsequently, the film is dried in a polymerization oven or using a heat press. The film with the pre-glued decorative motif is then transferred onto the pre-printed fabric. This process is called curing and takes about 20 seconds. When the fabric reaches room temperature, the cold-applied film is removed; hot-applied films can be removed immediately after opening the heat press.

The success of DTF printing

Realisaprint.it is an online print shop created in 2019 by Remy Barelli and Rafael Mari, exclusively targeting a reseller clientele of graphic arts and communication professionals (advertising agencies, graphic designers and freelance designers). In percentage terms, the customised sportswear segment currently accounts for 14% of total sales. Precisely because it does not work directly with the end customer, Realisaprint.it needs to keep prices competitive while guaranteeing high performance from both a technical and creative point of view. "Sportswear requires the use of quality raw materials, capable of ensuring high performance, comfort, breathability and above all resistance to wear and tear," explains Elisa Impellizzeri, Communication and Marketing Manager at Realisaprint.it. "Attention must be paid to every detail, including zips or hook-and-loop fasteners. From a creative point of view, we demand brightly coloured prints, attractive and modern designs, and customisation that reflects the individuality of athletes and, in general, of consumers interested in sportswear. This is why we try to ensure maximum customisation freedom on our site so that each customer can tailor the garments to their needs.”

The company offers different printing techniques (sublimation printing, direct-to-film, direct-to-garment) because adapting quickly to market demands is crucial to remain competitive. In recent years, there has been exponential growth in the DTF technique, which consists of printing an image onto an adhesive film and then transferring it onto a fabric using a hot press. "Digital printing offers huge creative possibilities for retailers, guaranteeing perfect graphic reproduction of images on any substrate, cost-effective printing even on small quantities and, in general, savings in terms of overall printing costs and energy resources," continues Impellizzeri. Each technique has advantages and disadvantages, and the team strives to help customers choose the one best suited to their needs. Specifically, DTF allows four-colour printing of very thin elements (up to 1 mm), even with white ink, reducing protrusions on the edges of printed images and eliminating the die-cutting phase typical of flock printing. It also adapts to different types of fabric: cotton, polyester, and viscose, guaranteeing resistance to washing and wear and tear, essential characteristics in the athleisure sector. DTG is suitable for printing on light-coloured fabrics composed of at least 70% cotton, but on the other hand, it requires pre-treatment of the print substrates.

Better on demand

For GedShop, a company specialising in printing customised clothing and accessories, the turnover from the sportswear segment is now around 10% of the total. With new technical materials and innovative decoration techniques on fabric, more and more sports associations and private individuals are turning to customisation. "If the printing techniques on fabric used to be screen printing and embroidery, today the high demand for customisation has encouraged a change also from a technological point of view," explains Alessandro Condello, co-founder of Gedshop. "Among the most popular techniques is the application of rhinestones, but also the use of fluorescent colours, glitter and digital printing, both direct and DTF. Screen printing is still the preferred choice for printing large quantities. Although there are concrete attempts to automate the screen printing process, it is still a craft technique which cannot guarantee the reduced error margins of the digital process. Therefore, despite higher costs, digital is still the preferred choice for certain customers due to the need for pre-treatment that some fabric types require. It remains, however, the technique that guarantees a fast and competitive printing process even on short runs, with virtually no machine set-up time.”

The future: special effects and process sustainability

The textile industry is today the main field of application for polyester, a synthetic fibre particularly appreciated for its ability to guarantee comfort, durability and resistance to abrasion. These characteristics make it suitable for clothing production, particularly in sportswear. One of the main challenges facing printers is to guarantee the same aesthetic features (both in print quality and 'hand', i.e. softness of the garment) as more traditional natural fibres such as cotton.

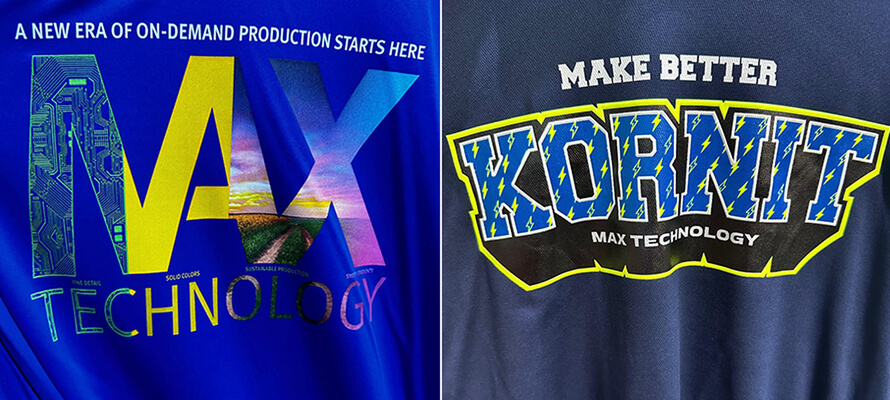

During the Kornit Fashion Week Tel Aviv 2022, Omer Kulka, Chief Marketing Manager of Kornit Digital, at the launch of the Atlas MAX POLY technology, emphasised how the fusion of fashion and sportswear is opening up new opportunities for printing on polyester, which is currently a fast-growing segment. In addition to incorporating Kornit's proven MAX technology for decoration on fabric, the machine aims to automate the process and make possible almost infinite combinations of special effects, such as threadless embroidery and three-dimensional printing, previously unattainable with a digital printing process. The demand for fairer and more sustainable production practices has reached an all-time high, not least due to increasingly stringent regulations, and suppliers such as Kornit Digital are directing their strategy towards localised, environmentally friendly production. It is a process that also involves intensive research and development aimed at producing increasingly eco-friendly chemicals and innovative fabrics that improve comfort and performance yet are sustainable.