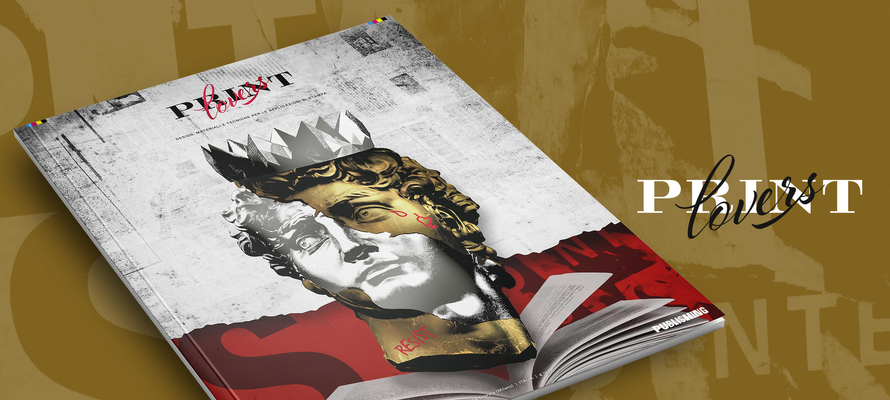

PRINTlovers #106 - Publishing

VIVE LE ROI!

A book opens, a crowned head emerges.

The king dies, and in the same gesture is reborn.

So it is with publishing: it changes its face, it transforms itself, but it never ceases to reign.

Each page is a farewell and at the same time a beginning, an act of courage that holds the promise of new splendour.

Design by O,nice! Studio

The paper used for the interior

GardaMatt Rough, produced by Cartiere del Garda, is a wood-free coated paper with a textured and slightly rough surface, combining the charm of natural paper with the performance of coated paper. Its duality is expressed in the print quality—precise details, bright colours, uniformity—and in the charm of untreated paper, with a volume of 1.1 that gives it a balanced and full-bodied texture, ideal for high-quality publishing projects. For the interiors of PRINTlovers, a weight of 120 g/m2 was chosen, capable of enhancing sharp images, deep contrasts, and vivid colours. More than just a medium, GardaMatt Rough is an expressive tool that makes paper an integral part of the editorial message.

The cover paper

Condat matt Périgord 250 g/m2

Condat matt Périgord is a high-quality, wood-free, matt-coated paper produced by Cartiere del Garda. It features an elegant and sophisticated matte surface, consistent thickness, and a special fibre composition that provides high volume, combining lightness and ease of handling - ideal characteristics for the publishing sector. It boasts a high degree of whiteness, ensuring intense colour rendering, high-contrast images, and vibrant colours. During printing, it offers excellent performance thanks to its machinability, excellent printability, and fast drying times, making it a reliable and high-performance optional even for demanding productions.

Coating and finishing

The cover features a KTM (KURZ Transfer Metal) silver coating, a new product introduced in Luxoro's offering, a thin, recyclable metallic layer that replaces traditional lamination. The neutral, reflective base highlights a face that seems to emerge from the surface thanks to KURZ's TRUSTSEAL® SFX technology. This three-dimensional optical illusion does not actually have any relief. The nuances of the face catch the eye and invite tactile discovery, while overprinted colour blocks demonstrate the material's compatibility with the use of inks. Hot-stamped accents in LUXOR® 392 metallic red add a dramatic touch and harmonise with the silver. The combination of KTM, SFX, and LUXOR® 392 demonstrates how surfaces can tell sensory stories while reducing environmental impact.

Metallisation

Metallisation was carried out by Plastigraf Trevigiana using the Zeroplast® process, developed for the luxury market: a technology that transfers an ultra-thin layer of painted aluminium to protect and enhance the cellulose substrate. The laminated product is therefore free of plastic film, which is recovered and sent for recycling (PIR), but has extreme brilliance and good scratch resistance, as well as suitability for subsequent printing enhancements. Here, Zeroplast® has been combined with Natureal engraving technology, which allows 3D depth effects to be added to the surface without relief.

Printing and finishing

Varigrafica received the metallised sheets using the Zeroplast® process, with which KTM was applied. The next step was to print a white reserve to give a matte effect to the four-colour process, while direct printing on the silver coating shows an iridescent and metallic effect. The print thus has a dual personality, creating an extraordinary contrast with a single offset pass using Komori H-UV. The only part not overprinted is the three-dimensional effect obtained with TRSTSEAL® SFX technology. The final step was finishing with LUXOR® 392 metallic red hot foil stamping and a single h+m cliché.