It's easy to say "packaging"

It’s easy to say “packaging”. But you realise just as quickly how broad and complex this definition really is. We therefore narrowed the field to flexible packaging, corrugated board and folding cartons: the most widespread packaging options, used from mass-market products to the high end. And we took stock of technological progress, materials and printing techniques with the three key associations in this sector: Giflex – Associazione Gruppo Imballaggio Flessibile, GIFCO – Gruppo Italiano Fabbricanti Cartone Ondulato – and GIFASP – Gruppo Italiano Fabbricanti Astucci e Scatole Pieghevoli.

By Roberta Ragona | on PRINTlovers 106

Corrugated is the new black

The global corrugated board market is worth over 134 billion dollars, with expected annual growth of 6% between 2023 and 2030, driven by e-commerce and demand for sustainable packaging (Grand View Research data). In the European market, growth stands at +4.8%, led by food and beverage, in particular fast-moving consumer goods (FMCG): products with a short shelf life due to high demand. Italy is the second-largest producer in Europe after Germany. Recorded production in 2023 fell by 4.2% compared to the previous year, with around 7.7 billion square metres produced versus 8 billion in 2022. Over the last decade, however, volumes are still on the rise and above pre-Covid levels. The most important segment is tertiary transport packaging, especially for the food sector, which absorbs 62.6% of production. In non-food, pharmaceuticals and pet food are among the fastest-growing markets. But what are the specific features of this type of packaging?

Corrugated board owes its mechanical strength and lightness to the way it is made: its simplest form – two flat paper layers (liners) held together by a corrugated paper medium using natural glue – has been in use since 1857. For greater strength, multiple layers can be superimposed, in double or triple wall, evenly separated by flat sheets. Triple-wall board is so strong that it can replace wood, while weighing significantly less. The choice of paper determines the nature of the finished product: the most common options are kraft paper (strong, made from virgin softwood pulp with 10–20% high-quality recovered pulp), liner and testliner (papers produced from selected recovered fibre composed of one or more layers). Another key variable is the fluting: reels are loaded into a machine that uses high-pressure steam and pressing to shape the corrugation. Flutes can differ in height and pitch, and vary in the number of flutes per linear metre and in the flute profile. High flutes offer the best vertical compression strength but lower printability; low flutes perform better under flat compression. Medium flutes offer a compromise between performance and paper consumption, with good printability and greater resistance to stress during converting, packing and shipping. Micro-flute is mainly used in combination: the most widespread format is “mini triple-wall”, which guarantees excellent printability and is also used for carton production.

In addition to assembly specifications, corrugated board is classified according to its resistance to compression, burst strength, water absorption capacity and flexibility. Thanks to advances in manufacturing and printing, there are corrugated packaging solutions suited both for transport and for display: these are aimed at large-scale retail, simplifying loading/unloading and shelf-ready display.

Flexographic printing is the most widely used technology, also thanks to technological progress in recent years that allows smaller print runs to be handled in shorter times, both in preprint and postprint modes – i.e. printing directly on the liner already glued to the fluting, or printing first and then laminating it onto the board. It is a direct printing technique: the ink is deposited directly onto the substrate via the inked printing cylinder (plate). It offers low production costs and high quality, also thanks to improvements in fine screening. Screen printing is also widely used, and among its advantages is the ability to work in large formats.

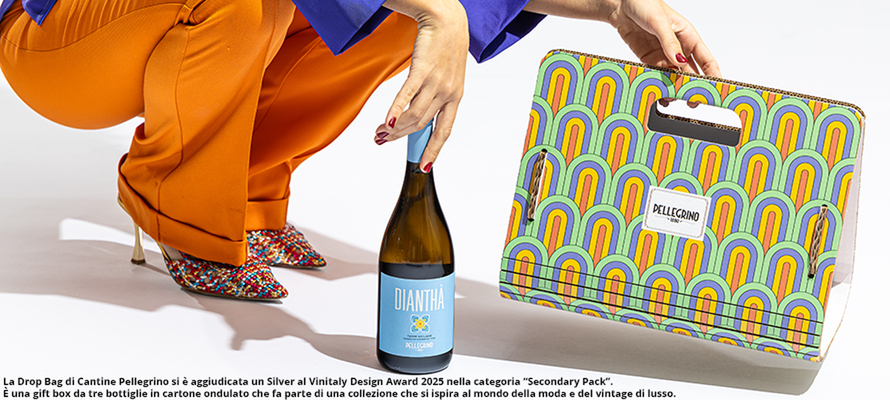

Digital printing, by contrast, uses a process that transfers ink without the use of plates or clichés: with this technique the ink is not absorbed directly but forms a layer that is fixed with a finishing step. During finishing, the surface can be made glossy or matt through lamination. The demand for finishing is not limited to pallets that become display units for large-scale retail: one area where more sophisticated corrugated packaging is increasingly requested is wine. As Andrea Mecarozzi, president of the Associazione Italiana Scatolifici, has pointed out, corrugated board packaging plays a crucial role for the wine sector, in a market that more and more often asks to transform the classic brown cardboard box into something special that enhances the purchase experience.

The major innovation of recent years is lightweighting in packaging, made possible by the evolution of converting machinery and higher-performance papers. The average grammage of corrugated board has fallen steadily: it now averages 532 g/m². It is estimated that in just over twenty years the reduction in grammage has been 12.1%. On the production side, research is focused on energy savings, with less energy-intensive processes and machinery and lower water consumption. Italy is the leading European country in the virtuous management of post-consumer material: 91.4% of paper and board packaging is sent for recovery, and 85.1% enters the recycling chain. Eighty per cent of corrugated board intended for packaging is made from recovered fibre.

Style and function of solid board

In the Italian market, solid board accounts for 15% of cellulose-based packaging. In 2023, partly due to price reductions along the supply chain, the Folding Cartons and Boxes sector recorded a moderate decline in turnover, while remaining well above pre-pandemic levels; 2024, however, has brought a recovery. The performance of packaging closely mirrors that of the manufacturing industry as a whole, moving in step in terms of demand and critical issues. Folding cartons are used as secondary packaging, 44.9% for food, 20.3% for beverages and 10.3% for cosmetics and pharmaceuticals.

Cartonboard or solid board is easy to process, and the different surface types – coated, matt, embossed, bleached or dyed in the pulp – allow for infinite graphic and converting possibilities. They can be made entirely from solid board of different grammages and treatments, or laminated, depending on the application. The most common combinations are with PE film or aluminium, the latter increasingly replaced by layers subjected to metallisation processes. The strength of cartons lies in their versatility: matt or glossy print effects, glossy and matt screen finishes, glitter and pearlescent UV varnishes, metallic or textured 3D-effect coatings, embossing and letterpress transform packaging into a sensory experience. Openings, windows, cuts and kiss-cuts give visibility to the product and variety to packaging design through dies or laser cutting. Laser die-cutting technology can be integrated during flatbed printing, saving significant time.

High-resolution offset printing technologies that can come into direct contact with food have made solid board very popular in foodservice, where it has replaced packaging made from other food-contact materials. In folding cartons too, the offer of active packaging has expanded with advanced functions, such as anti-odour or anti-oxidation layers, grease- and moisture-resistant layers. The latest development is the possibility of achieving these results through barriers made solely from cellulosic fibre (MFC – microfibrillated cellulose).

More sophisticated machinery can process thinner materials: currently the structural limit for cartonboard used in packaging is around 700–800 g/m², but technological advances have enabled a weight reduction of around 30%. Production improvements are accompanied by research into optimising the mix between virgin cellulose and recovered paper. Cartonboard fibre can be reused up to 25 times, becoming secondary fibrous material. The use of low-odour, low-migration inks and varnishes makes it possible to limit the use of plastic films, which are replaced by high-performance finishing, and inline cold-foil technology in offset printing has eliminated metallised plastic films, reducing costs. Finishes are not only aesthetic: embossing makes it possible to create 3D effects that make packaging “speak” in an accessible way, for example by using braille. One last important innovation concerns safety, with converting solutions that prevent an unsupervised child from opening a carton on their own: systems that are particularly useful in the pharmaceutical sector and in household cleaning products.

Flexible: versatile and with a sustainable future

According to a study on the European market published by Euromonitor/FPE, excluding beverages, flexible packaging is the largest segment of retail packaging in Europe. In Italy, the flexible packaging industry employs over 12,000 people, produces around 450,000 tonnes and has a turnover of roughly 4.5 billion euros, accounting for around 80% of total production. The most important application sector is food, which represents 80% of output. Fresh products and convenience food (portionable products suitable for out-of-home meals) have driven its evolution, in particular ready-to-eat fruit and vegetables.

The formats available are countless: among the main ones are sachets, bags, clip bags, flow bags, flowpacks, pouches, vacuum “brick” packs, doypacks and cheerpacks. The most dynamic are pouches: the arrival of zip pouches and press-to-close pouches has broadened usage occasions, from single-use packs for short-term consumption to pantry or fridge products in reclosable packaging.

Twenty per cent of non-food flexible packaging production is split between pharma, pet food, home care and personal care. In cosmetics, single-dose packs dominate, while in home care and personal care stand-up pouches are widespread. In particular, refill solutions for detergents and hygiene soaps are among the packaging formats with the greatest development potential. Securing institutional, customer, consumer and environmentalist recognition of flexible refill packaging as a valid alternative to rigid packaging is one of the major issues on which Giflex itself is working, through a targeted path of institutional recognition and validation.

Today, 70% of flexible packaging is recyclable, but the real challenge is the shift from “recyclable” to “recycled”: many plants are not yet equipped for the sorting of multilayer flexible materials and for mainstream recycling streams. Among future opportunities, chemical recycling is certainly one of the sector’s expectations.

The technological evolution of the segment will be driven by alignment with European regulations, particularly the PPWR, Packaging and Packaging Waste Regulation, which came into force at the beginning of the year and sets out a number of directions that will need to be addressed. At the same time, the Regulation also represents an opportunity for flexible packaging, thanks to increased recyclability, the sustainable use of resources and innovative refill solutions.

As regards printing, the techniques depend on run lengths and end use: for large volumes, gravure printing offers competitive costs and consistent print quality. As an alternative to gravure, flexographic printing is used; it is now widely adopted and guarantees great versatility, especially for medium and short runs. In recent years, digital printing has begun to gain ground, offering a solution for very short runs and for print personalisation, thanks to the possibility of differentiating every single printed pack.

Looking ahead, however, the best approach is expected to be the use of hybrid presses, i.e. machines that combine several printing techniques and therefore become more versatile, as they can offer different printing solutions.