Ecofibres, textile’s Back to the Future

While it is true that textiles originated from natural fibres (hemp, linen, cotton), industrialisation has led to the creation and large-scale spread of synthetic and artificial fibres. And now that sustainability is a priority for brands, innovation is mainly focused on new bio-based substrates. But what exactly are they, and how are they made? We try to provide some answers with Anna Pellizzari (Materially), Laura Fiesoli (Museo del Tessuto), Francesca Nori (Vérabuccia®) and Roberto Lucini (Creazioni Digitali).

By Caterina Pucci | On PRINTlovers 97

Sustainable innovation in the textile industry is making great strides. The sustainability of products and processes has become a priority for many brands, and producing substrates from organic waste, which seemed like science fiction until a few years ago, has become a reality. In the ecofibre market – worth $35 billion in 2021 - more and more companies are working on producing alternative fibres derived from hemp, wood pulp, coffee grounds and algae. There is an emerging industry related to producing natural dyes to replace the toxic substances traditionally used to treat and dye fibres. Recently, Stella McCartney launched a collection of biodegradable denim made from Candiani's innovative COREVA stretch fabric (which we reported on in PRINTlovers issue 96). Companies such as Salvatore Ferragamo and H&M, for their Conscious Collection, use Orange Fiber - obtained from orange processing waste - and Hugo Boss has produced its vegan trainers in Piñatex, an alternative to leather made using pineapple leaves. The biggest challenge lies in converting individual initiatives into structural change. In the following pages, we try to take stock of the situation through industry professionals' experiences and best practices.

Sustainability as a driver of innovation in fashion

To begin this journey to discover bio-based materials, we interviewed Anna Pellizzari, Executive Director of Materially, which has been connecting manufacturers and companies in search of sustainable solutions for 20 years. First, it should be pointed out that in the textile sector, bio-based fibres are not a recent innovation: on the contrary, the fabric originated from natural fibres (hemp, linen, cotton). With the industrialisation of processes and of the market, research and development have led to the creation of artificial cellulosic fibres, viscose primarily, which are based on the chemical transformation of cellulose to generate a yarn with different mechanical characteristics and performance properties compared to natural fibres. Similarly, artificial fibres are created from bio-based sources such as castor oil (for nylon) or polysaccharides (for polyester) and natural polymers such as chitin, casein, etc. “With the sharp increase in textile consumption in recent years, which is estimated to double by 2030, there has been an increased interest in alternative sources of raw materials to those currently used, particularly cellulose, which is widely available,” explains Pellizzari. "Research is focusing in particular on innovative processes to make the supply chain less impactful: for example, the aim is to make unexplored sources of cellulose accessible, such as by-products from the food and forestry supply chain. A case in point is the research and innovation project GRETE - Green chemicals and technologies for the wood-to-textile value chain - which has led to the development of modification processes for wood pulp, making it usable in the regeneration of textile fibres. Apart from the raw material used, it is above all the transformation processes that define the environmental impact of the textile value chain: the use of chemicals that are difficult to manage or the large consumption of fresh water. "To be relevant for the market and industrially scalable, the “new” fibres must have the same technical characteristics as traditional fibres.

An interesting example is the processes developed by Nike for additive manufacturing in textiles: first applied in footwear, with the Flyknit technology, and now also in apparel with the Nike Forward Platform, they aim to reduce impact overall, cutting production steps, eliminating raw material waste and ultimately cutting emissions,” adds Pellizzari. "The big luxury brands, starting with the Kering Group, are already committed to making sustainability the primary driver of innovation, supporting research, sponsoring start-ups, and participating in collective round table discussions to give fashion new rules. The risk is to over-communicate on green materials, generating consumer confusion as to what is actually effective. Greenwashing is unfortunately still very strong.”

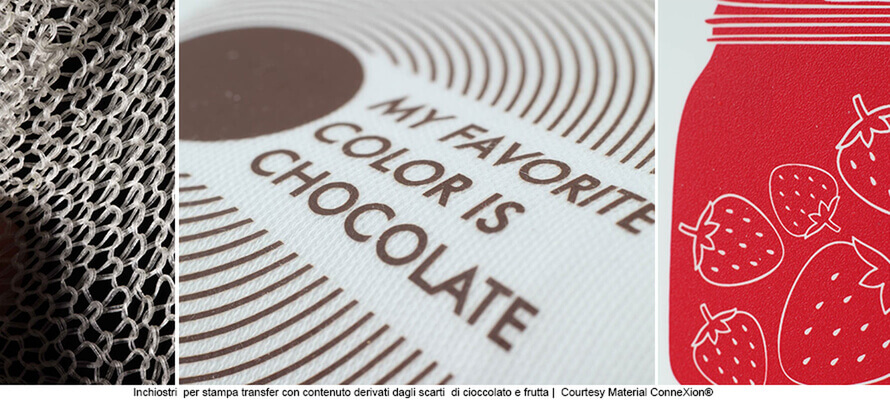

Regarding printing processes, bio-based synthetic fibre fabrics have no technical limitations compared to traditional ones. Actually, in some cases, it is even possible to improve performance. "For example, the fibre developed in the GRETE project facilitates dye absorption, reducing water consumption in finishing processes. Interesting thermal transfer films are produced using inks derived from natural colours from foodstuffs. These are water-based inks consisting of 18% chocolate and 15% strawberry extract, but also with colours derived from matcha tea. They comply with OEKOTEX and REACH certifications and can be applied to various natural and synthetic fabrics, as well as leather and velvet, currently listed in the Material ConneXion database, which we partner with in Europe.”

Among the start-ups that have received several expressions of interest in the fashion industry, leading to the development of several capsule collections, Pellizzari mentions Infinited Fiber, with its Infinna™ fibre, and Spinnova, which offers an even more sustainable process. The former is a cellulosic fibre made through a process based on ionic liquids, which has already been tested by several brands, such as Tommy Hilfiger, which launched a T-shirt collection last summer. Spinnova, on the other hand, has created a capsule with Adidas, in which the fibre is used in a blend with cotton to make the yarn used in a line of hoodies.

What does 'sustainable' mean today?

The Museo del Tessuto in Prato is the largest cultural centre in Italy dedicated to promoting historical and contemporary textile production and art. Inside it, in 2021, the Textile Library was inaugurated, an archive of contemporary fabrics, fibres, yarns and materials that is constantly updated and evolving. The materials come from leading international companies from all sectors, start-ups and research centres. A prominent role is played by the companies of the Prato textile district: wool mills, yarn manufacturers, raw material companies, and finishing and dyeing plants are the main contributors to the Textile Library. In this way, the museum intends to communicate the relationship that has bound it to the production context of the area since its beginnings, enhancing its innovative abilities and technical and stylistic know-how. Particular attention is paid to the circular economy and sustainable innovation. "What emerges from the collection is that there are indeed industrialised materials already on the market that could largely replace traditional fabrics, bringing benefits to the environment through the use of recycled fibres or from renewable sources," explains Laura Fiesoli, Textile Expert and curator of the Textile Library. "At the same time, sustainable textiles are clearly only one element of a new, circular business model that the fashion industry should adopt, and that includes a new use of energy resources, logistics and, to a large extent, a new understanding of human and workers' rights."

Sustainability is a value that the manufacturing company seeks in the entire production process. If a natural textile is produced with the abuse of energy resources or without respecting workers' rights, then it cannot be called sustainable. Sustainability is a value that concerns the product and the process in the same way. "There are many virtuous companies in Italy, especially in the Prato district that we follow most closely. What must be overcome is undoubtedly the stumbling block of entering a fashion market dominated by fast fashion and, therefore, very low prices. Unfortunately, in general, a sustainable product still has a higher cost and not all brands are willing to pay more for the raw material by sacrificing their profit margin.”

Fabrics for fashion from waste

One of the companies featured in the Textile Library is Vérabuccia®, a circular economy project founded in 2020 by Francesca Nori and Fabrizio Moani, thanks to which fruit peel is transformed into a new material. With the technological support of an Italian chemical company with an innovative vision, Nori's idea of using fruit skin, developed during her academic studies, came to fruition. This is how Ananasse™ was born, the first product obtained from pineapple using an innovative (patented) production process that gives the peel the application and stability characteristics of traditional leather without transforming or flattening the pineapple's epidermis, maintaining the initial aesthetic appearance of the plant's scaly surface, similar to that of a reptile, but acquiring new and high-performance application characteristics.

Ananasse™ is produced in sheets that are small but manageable and, therefore, variable according to their final use. Upstream of the drying, trimming and pressing phases, the material undergoes a further final step (currently manual) on the texture, in the case of the variant without bracts (i.e. the natural fins present on the surface), giving rise to a further aesthetic offering, which does not affect either the structure or the type of application. Colouring and the various processes that can be performed on the surface (drilling, lasing, die-cutting or engraving) allow for further diversification of the original appearance and the creation of innovative and diverse colour and texture effects.

"Sustainability is the prerequisite for an ongoing project for human beings and their habitat, which can only be achieved through constant investment in research and development to obtain answers and offer better actions than the current methods and business models. We do not believe that the new material types represent a critical limiting factor for printing operations if we think, for example, of the industrial 3D printing process implemented by bio-based matrices reinforced with natural fibres. But the aesthetic trend emerging in recent years is definitely more aimed at leaving materials as “natural” as possible,” explains Nori.

Vérabuccia® is aimed at a market made up, at present, mainly of fashion and design brands belonging to the high-end, luxury segment, more aware or in transition, often also with a significant background tied to animal leather, but who want as much to affirm their commitment to the planet and its species as to make themselves stand out in the use of the raw material used without giving up on the aesthetic and tactile pleasure, with the use of innovative bio-based materials. Following important feedback received in 2022 with the start of sample distribution and production of the prototypes, in January 2023, major material upgrading processes were undertaken in Italy to expand the demand for the use and application of the material.

"Our team uses complementary external figures with decades of expertise to manage the areas not under their specific expertise and is constantly working to try to contribute, albeit in a small way, its own added value, continuing to optimise the patented technology through research and development. This is also thanks to ongoing synergies with experts in the sector, and at the same time to committing itself socially," adds Nori. Among its numerous recognitions, the most recent is the exhibition at the Wemed Mediterranean Sustainability Award 2022 ceremony, held at the San Pau Recinte Modernista in Barcelona. Also in November, Vérabuccia® joined the Italian Circular Economy Stakeholder Platform (ICESP). "The future goal is to encourage the creation of industrial symbiosis to succeed in the current circular economy and actively introduce Vérabuccia® in the fashion and design sectors.

Can ecofibres be digitally printed?

Creazioni Digitali began its involvement in sustainable printing in 2016 by planning to include digital pigment textile printing, i.e. water-based direct digital printing on multi-fibre fabric (GreenDrop), in its production offering. Until then, but still today, the most widely used technology has been dye sublimation, which, although it does not use water, only allows the printing of single-fibre fabrics. In 2021, the partnership with the Israeli company Kornit Digital led to the creation of an Experimental Centre (CreŌ - Creation Opportunity), which allows, in addition to regular production, experimentation with new developments and also to offer innovative start-ups the opportunity to print their own products in small quantities. The Kornit Digital machines guarantee a water saving of 4995 l x 1000 m, which then requires treatment for its purification. "Up until a few years ago, the problem of the textile industry's environmental impact was not a particularly high priority – to such an extent that our proposals were met with a token interest, but not an operational one. Since 2020, however, the race towards green has exploded, and not always with coherent intentions," explains Roberto Lucini, founder of Creazioni Digitali. "Brands are aligning themselves and, above all, are increasingly insisting that their supply chain be updated. From our point of view, the commitment is, above all, to offer sustainable digital printing in classic fabric production for quantitative effectiveness. Of course, the experimentation also concerns fabrics with a high degree of sustainability.”